Electronic scoring targets in sports shooting are advanced technology solutions that provide accurate and efficient scoring in shooting competitions. These systems have largely replaced traditional paper targets and manual scoring processes in many shooting disciplines. For the shooter, an electronic scoring system can provide accurate and instant feedback on scores digitally. This allows for many calculations to be performed on the shots instantly, giving the shooter a lot of valuable information.

How do electronic scoring systems work?

Electronic scoring target systems can triangulate the point at which a bullet hits the target. This allows them to assign scores and give feedback in real time.

Electronic scoring targets consist of multiple layers of specialized materials. The front layer is usually made of a durable material like rubber or polymer, which can withstand the impact of the bullet or projectile. Behind this layer, there are sensors or electronic components responsible for registering and analyzing the shots.

The key component of an electronic scoring target is its sensor array. This array consists of multiple sensors placed strategically behind the target surface. The number and arrangement of sensors may vary depending on the system's design and purpose. The sensors can be optical, acoustic, or electromagnetic, depending on the technology employed.

When a projectile hits the target, the sensors in the array detect the impact. The specific sensor technology used determines the detection method. We will cover that in more detail in the following paragraphs. The scoring system receives the signals from the sensors and processes the data to determine the location and score of the shot. This processing is typically done by specialized software or algorithms that analyze the information from the sensors. Once the scoring system has processed the data, it generates a score for each shot. The scores are then displayed on a digital screen near the shooter or transmitted wirelessly to a central scoring display. This allows both the shooters and spectators to see the results in real-time.

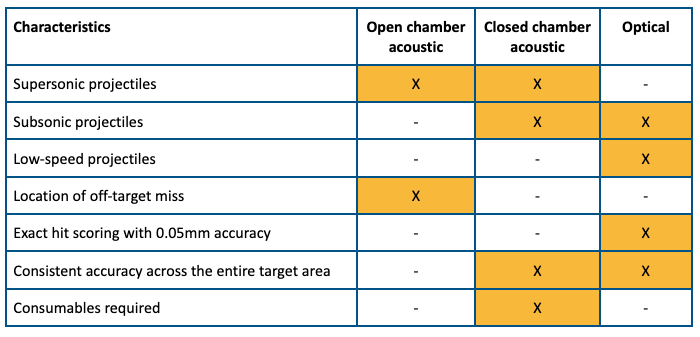

There are three major types of electronic scoring technologies which are used on the market.

Overview of different electronic scoring systems

Open chamber acoustic measurement

This scoring technology utilizes vibration or piezoelectric sensors, which are typically positioned either beneath the target frame or at each corner of the frame. It enables the identification of supersonic projectiles and is frequently employed in military shooting ranges for defense purposes. The primary benefit is its ability to detect bullets within a wide detection area. Consequently, it not only allows users to observe their hits on the target but also record any misses outside the target area, accurately determining the precise location of those off-target misses. These features also contribute to its popularity among hunters and long-distance rifle shooters, as it facilitates rapid weapon and scope alignment and provides a means for practicing in challenging wind conditions.

Closed chamber acoustic measurement

When it comes to electronic scoring, this method is the original and oldest among all electronic scoring systems. It employs piezoelectric sensors that function through vibration. However, in this case, the sensors are positioned within a confined chamber. The target frame contains the sensors and is covered by a rubber roll or paper to create a sealed environment around them. When a bullet enters the chamber, it generates circular waves similar to those created when a rock is thrown into the water. These waves are then detected by the sensors, enabling precise calculation of the hit position. This type of system has its advantages and disadvantages. On the positive side, it can detect nearly all types of projectiles, ranging from sub-sonic pistol rounds to supersonic big-bore rifle calibres. However, a drawback arises when the chamber is subjected to heavy usage, as bullets can tear the chamber, resulting in larger openings. Consequently, if a subsequent bullet lands precisely in the previous bullet hole, it will go undetected. This means regular maintenance and specific consumables are necessary for the system to operate effectively.

Optical Measurement Scoring System

As the name might suggest, instead of using vibration, light is used to detect the bullet's position. In such systems, there is always an emitter and a receiver. The emitter is a light source of any kind. It can be a light diode, laser beams or continuous diffused LED light strips.

These receivers capture the light and any changes in the light pattern itself. So what happens is that when a bullet passes the measurement frame, it penetrates the light field and casts a shadow on the receivers. With the help of specialized algorithms, calculations can be done and the exact bullet position located. With modern sensors, this is the most accurate scoring technology type on the market, as it can record the bullet position with as little as 0.05mm from its real position. This is why it's being used for all modern high-level shooting competitions.

The latest and most innovative electronic scoring technology in the market is TrueScore technology, developed by INTARSO in 2022. INTARSO team has spent years testing and evaluating different scoring technologies to develop unprecedented precision in electronic scoring technology not yet seen on the market.

TrueScore electronic scoring technology uses a light curtain that produces a light plane for accurate hit detection. When the bullet passes through the light curtain, it creates a shadow. The two-line cameras capture the bullet shadow and perform high-speed image processing for hit recording. The cameras are taking 160 000 photos per second. This guarantees that any type of bullet will be detected at any known speed at our promised accuracy. A highly intelligent calibration algorithm performed on every individual unit ensures the same accuracy over the whole detection area.